As the crafting community increasingly prioritizes sustainability, the debate over material choices has intensified. Among synthetic fibers, Polyester Yarn and acrylic yarns dominate the market due to their affordability and versatility. But when scrutinized through an environmental lens, which option aligns more closely with eco-conscious values?

1. Raw Materials & Production: A Petrochemical Footprint

Both Polyester Yarn and acrylic are derived from fossil fuels.

Polyester Yarn is made from purified terephthalic acid (PTA) and ethylene glycol, primarily sourced from petroleum. Its production involves energy-intensive processes, including polymerization and extrusion, which emit significant greenhouse gases (GHGs). However, advancements in recycled Polyester Yarn (rPET)—made from post-consumer plastic bottles—have reduced its reliance on virgin fossil fuels. Brands like Patagonia and Repreve now champion rPET as a "closed-loop" solution.

Acrylic, synthesized from acrylonitrile (a toxic compound linked to carcinogenic risks), requires even more hazardous manufacturing. The polymerization of acrylonitrile releases volatile organic compounds (VOCs) and nitrous oxide, a potent GHG. Unlike Polyester Yarn, acrylic lacks a robust recycling infrastructure, leaving most production dependent on virgin materials.

Verdict: Polyester Yarn edges ahead due to recycled alternatives and marginally lower toxicity in production.

2. Durability & Microplastic Pollution

Synthetic yarns shed microplastics during washing, contaminating waterways.

Polyester Yarn fabrics release microfibers at a higher rate than acrylic, especially in blends with natural fibers. A 2020 study by Nature Sustainability found that Polyester Yarn fleece sheds up to 1,900 microfibers per wash.

Acrylic sheds fewer microplastics but degrades faster under UV exposure and heat, shortening garment lifespans. Its lower durability means frequent replacements, indirectly increasing resource consumption.

Verdict: Acrylic’s shorter lifespan and lack of mitigation strategies make Polyester Yarn the lesser evil here.

3. End-of-Life Scenarios: Recycling vs. Landfill

Both materials struggle with circularity, but pathways differ.

Polyester Yarn can be mechanically or chemically recycled, though mechanical methods weaken fiber quality over time. Chemical recycling (e.g., depolymerization) offers a more sustainable route but remains cost-prohibitive. Initiatives like the Textile Exchange’s 2030 Recycled Polyester Yarn Challenge aim to scale these solutions.

Acrylic is notoriously difficult to recycle. Its complex polymer structure resists breakdown, and most facilities lack the technology to process it. As a result, 85% of acrylic waste ends up in landfills or incinerators, releasing toxic dioxins when burned.

Verdict: Polyester Yarn’s recyclability—even with limitations—gives it a critical advantage.

4. Alternatives and Mitigation Strategies

For crafters committed to sustainability, neither Polyester Yarn nor acrylic is ideal. However, pragmatic steps can reduce harm:

Opt for recycled Polyester Yarn over virgin synthetics.

Pre-wash synthetics with microfiber filters.

Choose natural fibers (e.g., organic cotton, hemp, or wool) for projects where durability and biodegradability matter.

While neither Polyester Yarn nor acrylic is inherently sustainable, Polyester Yarn emerges as the marginally better option due to its recycling potential and evolving eco-innovations. However, the crafting community must push beyond synthetics, advocating for systemic shifts toward regenerative materials and circular economies. True sustainability lies not just in choosing “less harmful” plastics but in reimagining our relationship with resources altogether.

英语

英语 中文简体

中文简体

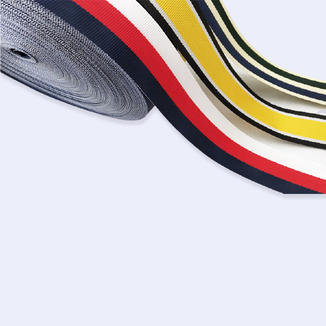

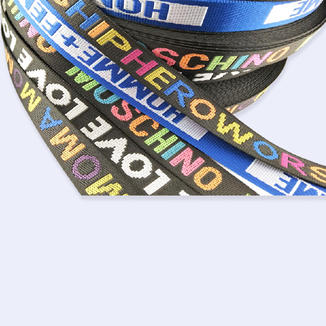

100% Polyester Series

100% Polyester Series