Technical textiles represent a rapidly growing segment of the global textile industry, characterized by products designed for specific functional performance rather than aesthetic appeal. Among the various materials utilized, Polyester Yarn stands out due to its versatile properties, including high tensile strength, durability, and resistance to environmental factors.

Overview of Polyester Yarn in Technical Textiles

Polyester Yarn is a synthetic fiber derived from petroleum-based polymers, known for its exceptional mechanical properties and adaptability. In technical textiles, it is often preferred for its ability to be engineered to meet specific requirements, such as moisture-wicking, UV resistance, and thermal stability. The use of Polyester Yarn has expanded significantly due to advancements in production techniques, enabling its integration into high-performance applications.

Key Characteristics

Polyester Yarn exhibits properties that make it suitable for technical textiles, including high abrasion resistance, minimal shrinkage, and compatibility with various coatings and treatments. These attributes contribute to its widespread adoption in industries demanding reliability and longevity.

Industrial Applications of Polyester Yarn

In industrial settings, Polyester Yarn is employed in products that require robust performance under strenuous conditions. Its applications span multiple domains, from filtration to protective gear.

Filtration Systems

Polyester Yarn is commonly used in filter fabrics for air and liquid filtration. Its fine denier and consistent fiber structure allow for efficient particle capture, making it ideal for industrial filters in sectors like manufacturing and environmental management. For instance, Polyester Yarn-based filters are utilized in dust collection systems and water treatment plants.

Protective Clothing

Due to its resistance to chemicals and flames when treated, Polyester Yarn is incorporated into protective garments for workers in hazardous environments. Examples include coveralls and gloves designed to shield against splashes, sparks, or abrasive materials.

Medical and Healthcare Applications

The healthcare sector leverages Polyester Yarn for its hypoallergenic properties and ability to maintain sterility. It is used in various medical textiles that prioritize patient safety and hygiene.

Surgical and Hospital Textiles

Polyester Yarn is found in surgical gowns, drapes, and bedding, where its durability and ease of sterilization are critical. Additionally, it is used in woven and non-woven formats for products like wound dressings and orthopedic supports, providing comfort and functionality.

Hygiene Products

In disposable medical textiles, such as underpads and wipes, Polyester Yarn offers absorbency and strength, contributing to efficient infection control practices.

Automotive and Transportation Applications

The automotive industry relies on Polyester Yarn for components that enhance safety, comfort, and vehicle performance. Its applications range from interior furnishings to structural parts.

Safety Components

Polyester Yarn is integral to seat belts and airbags due to its high tensile strength and energy absorption capabilities. These features help meet stringent safety standards in vehicles.

Interior and Exterior Textiles

In car interiors, Polyester Yarn is used in upholstery, carpets, and headliners for its resistance to wear and fading. Externally, it may be found in tire cord fabrics, which reinforce tires and improve durability.

Construction and Geotextile Applications

In construction, Polyester Yarn contributes to geotextiles and building materials that require long-term stability and environmental resistance. These applications support infrastructure development and erosion control.

Geotextiles for Soil Stabilization

Polyester Yarn-based geotextiles are employed in road construction, land reclamation, and drainage systems. They provide separation, filtration, and reinforcement functions, reducing soil erosion and enhancing structural integrity.

Roofing and Insulation Materials

Polyester Yarn is used in roofing membranes and insulation products for its waterproofing and thermal properties. It helps extend the lifespan of buildings by withstanding weather extremes.

Advantages of Polyester Yarn in Technical Textiles

The widespread use of Polyester Yarn is driven by several advantages that align with the demands of technical applications.

Durability and Longevity

Polyester Yarn maintains its integrity under repeated stress and exposure to elements, reducing the need for frequent replacements in applications like industrial fabrics or automotive parts.

Chemical and Environmental Resistance

Its inherent resistance to acids, alkalis, and UV radiation makes Polyester Yarn suitable for outdoor and chemical-intensive environments, such as in agricultural covers or marine textiles.

Cost-Effectiveness and Versatility

Polyester Yarn offers a balance of performance and affordability, allowing for scalable production across various technical textile sectors. It can be blended with other fibers or treated to achieve specific functionalities.

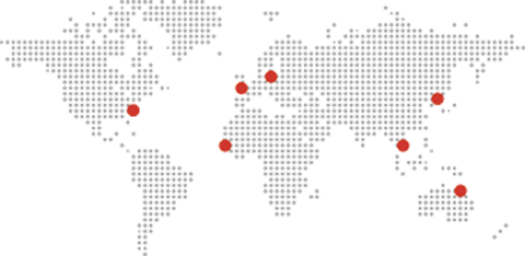

Polyester Yarn plays a critical role in the technical textiles industry, with applications spanning industrial, medical, automotive, and construction sectors. Its combination of strength, resistance, and adaptability makes it a preferred material for high-performance products. As innovation continues, the use of Polyester Yarn is expected to evolve, further solidifying its importance in functional textile solutions.

英语

英语 中文简体

中文简体

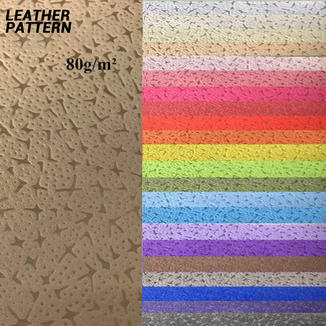

100% Polyester Series

100% Polyester Series