In the textile industry, the demand for low-maintenance and durable fabrics continues to grow. A key factor in meeting this demand is the use of polyester yarn, which significantly improves a fabric’s resistance to wrinkling.

Molecular Structure and Elastic Recovery

The inherent wrinkle resistance of polyester yarn stems from its polymer structure. Polyester is a synthetic polymer composed of long-chain molecules with strong covalent bonds. These molecules are highly elastic and can return to their original shape after being bent or compressed. Unlike natural fibers such as cotton or wool, which may permanently deform under stress or moisture, polyester fibers exhibit high elastic recovery. This property allows fabrics made with polyester yarn to resist creasing and maintain a smooth appearance even after mechanical action or prolonged wear.

Low Moisture Absorption

Another important characteristic of polyester yarn is its hydrophobicity, or low moisture absorption. Natural fibers tend to absorb moisture from the environment, which weakens hydrogen bonds within the fiber structure and makes them more prone to wrinkling. In contrast, polyester does not readily absorb water. As a result, fabrics containing polyester yarn are less susceptible to wrinkling under humid conditions or after exposure to perspiration.

Blending with Other Fibers

Polyester yarn is often blended with natural or other synthetic fibers to optimize fabric performance. For example, in poly-cotton blends, the polyester component provides structural stability and wrinkle resistance, while cotton offers softness and breathability. The polyester yarn within the blend helps lock the other fibers in place, reducing the likelihood of permanent crease formation. This synergy allows manufacturers to produce fabrics that are both comfortable and easy to care for.

Fiber Engineering and Yarn Construction

Advances in fiber engineering have further improved the functional properties of polyester yarn. Through texturing processes such as false-twist or air-jet texturing, polyester filaments can be given crimp, bulk, and stretch. This modified structure enhances the ability of the yarn—and ultimately the fabric—to absorb strain without forming visible wrinkles. Additionally, the fineness and cross-sectional shape of polyester fibers can be tailored to improve resilience and surface smoothness.

Role of Finishing Treatments

While polyester yarn itself contributes greatly to wrinkle resistance, finishing treatments can provide additional benefits. For instance, heat-setting—a process commonly applied to polyester及 blended fabrics—uses heat to stabilize the yarn’s molecular orientation, resulting in a durable flat surface. Such treatments complement the innate properties of polyester yarn, yielding long-lasting wrinkle resistance without significantly altering hand feel or aesthetics.

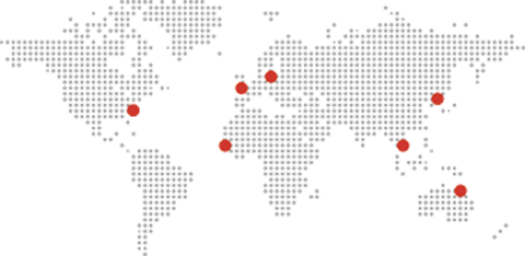

Polyester yarn enhances fabric wrinkle resistance through a combination of molecular elasticity, low moisture uptake, and advanced manufacturing techniques. Whether used in pure form or in blends, it helps create fabrics that require less ironing and maintain a neat appearance over time. These properties make polyester yarn a practical choice for applications ranging from everyday apparel to technical textiles where durability and easy care are essential.

英语

英语 中文简体

中文简体

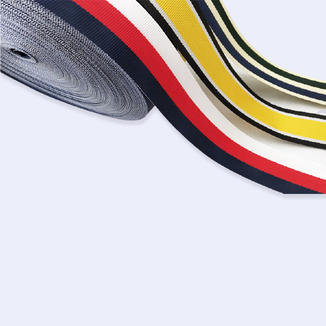

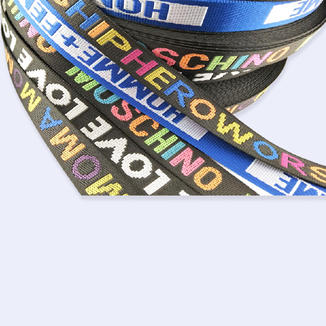

100% Polyester Series

100% Polyester Series