In the world of textiles and manufacturing, few materials are as ubiquitous and versatile as the polyester yarn. From the clothing we wear daily to the upholstery in our homes and cars, this synthetic fiber is a fundamental building block of modern industry. But what exactly is a polyester yarn, and what gives it such widespread appeal?

Definition and Basic Composition

At its core, a polyester yarn is a continuous length of interlocked fibers, all composed primarily of synthetic polymers. The term "polyester" refers to a category of polymers whose molecular backbone contains the ester functional group. The most common type used in textile production is polyethylene terephthalate, known as PET.

The raw material for most polyester yarn begins with purified terephthalic acid (PTA) or dimethyl terephthalate (DMT) and monoethylene glycol (MEG). These petrochemicals undergo a polymerization process to create a molten, honey-like substance. This substance is then extruded through a spinneret—a device resembling a showerhead—to form long, continuous filaments.

The Production Process: From Polymer to Yarn

The journey from polymer chips to finished polyester yarn involves several key steps:

Melt Spinning: The polymer chips are melted and forced through the spinneret to form filaments.

Drawing (Orientation): The freshly extruded filaments are weak and require strengthening. They are drawn (stretched), which aligns the polymer molecules along the filament's axis. This process significantly increases the yarn's tensile strength, durability, and resilience.

Texturing: To make the yarn more suitable for apparel, the smooth, straight filaments are often texturized. This process introduces curls, coils, or crinkles, adding bulk, stretch, and a more cotton- or wool-like feel, mitigating the sometimes slick texture of pure filament yarn.

Staple Spinning (Alternative Method): Instead of being kept as continuous filaments, the extruded polymer can be cut into short, predetermined lengths to create staple fibers. These fibers are then spun on a ring or open-end spinning system, similar to cotton or wool, to create a spun polyester yarn. This type of yarn is often blended with other natural fibers.

Key Characteristics and Properties

The dominance of polyester yarn in the market is due to a specific set of advantageous properties:

High Strength and Durability: Polyester yarn is exceptionally strong, resistant to abrasion, and retains its shape well, making it long-lasting.

Wrinkle and Shrink Resistance: Garments made from polyester yarn are known for their ability to resist wrinkling and maintain their dimensions after washing.

Quick Drying: The fiber is hydrophobic, meaning it repels water. It absorbs very little moisture, allowing it to dry much faster than natural fibers like cotton or wool.

Color Fastness: Polyester yarn accepts dye well and can hold vibrant colors without significant fading from washing or exposure to light.

Chemical and Mildew Resistance: It is resistant to many chemicals and is not susceptible to damage from mildew or molds.

Primary Applications

The properties of polyester yarn make it suitable for a vast range of applications:

Apparel: Used in everything from professional wear and dresses to outdoor jackets, sportswear, and fleece garments. Its moisture-wicking properties are particularly valued in activewear.

Home Furnishings: A primary material for curtains, upholstery fabrics, bed sheets, and pillowcases due to its durability and stain resistance.

Technical Textiles: Used in manufacturing seatbelts, conveyor belts, hoses, tarpaulins, and geotextiles for its high strength-to-weight ratio.

Industrial Uses: Employed in tire reinforcements, ropes, and nets.

Non-Woven Fabrics: Found in products like interfacing, disposable medical fabrics, and insulation.

Considerations and Blends

While pure polyester yarn offers many benefits, it can sometimes be less breathable than natural fibers. To balance performance and comfort, it is frequently blended with others. Polyester-cotton blends are among the most common, combining the softness and breathability of cotton with the strength and easy-care properties of polyester.

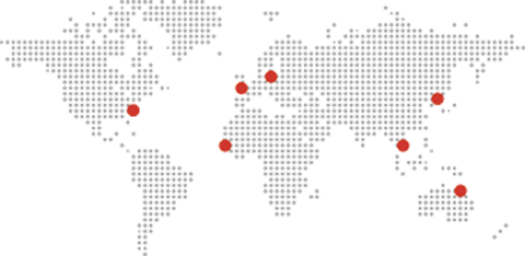

A polyester yarn is a synthetic workhorse of the textile industry. Its engineered properties of strength, durability, easy care, and versatility ensure its continued role as a critical material across countless sectors, from fashion to industrial manufacturing. Understanding its composition and characteristics is essential for anyone involved in the creation, selection, or use of modern fabrics.

英语

英语 中文简体

中文简体

100% Polyester Series

100% Polyester Series